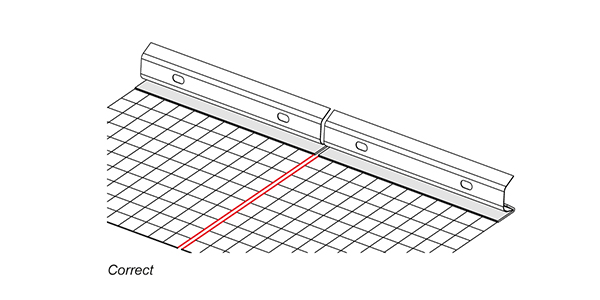

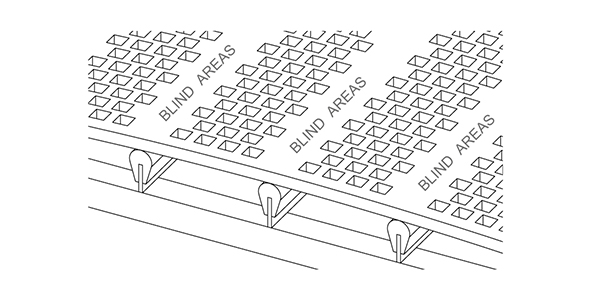

· Make sure to spread the material feed evenly to the full width of the screen bed in order to use the complete screening surface of the deck.

· Reduce feed height to avoid high impact on the screening media.

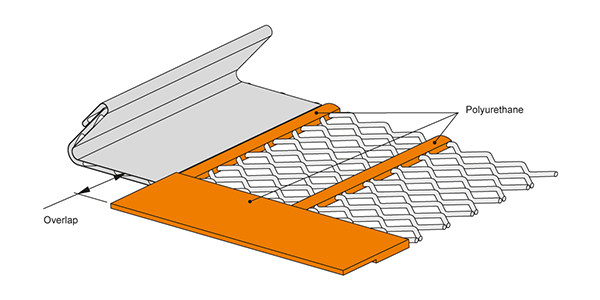

· Use the correct screening media, you may want to use at the feed end perforated plates, rubber or polyurethane that have a higher resistance to high impact and abrasion.

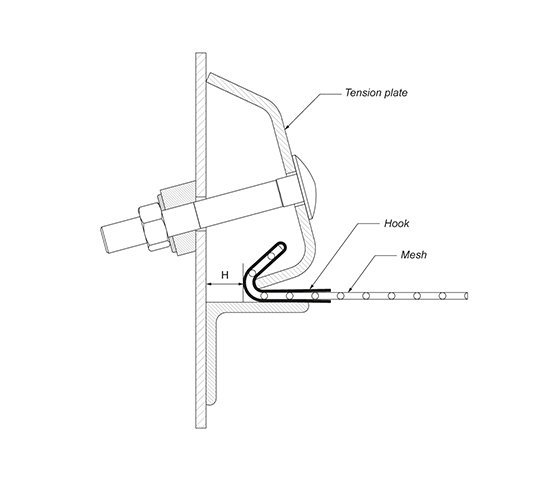

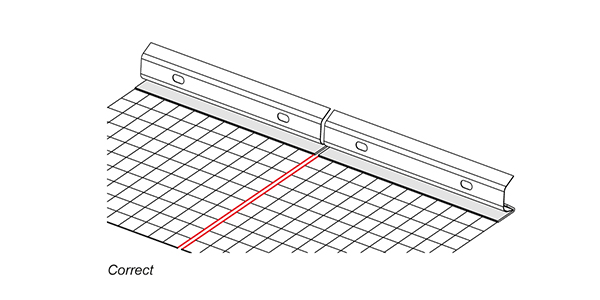

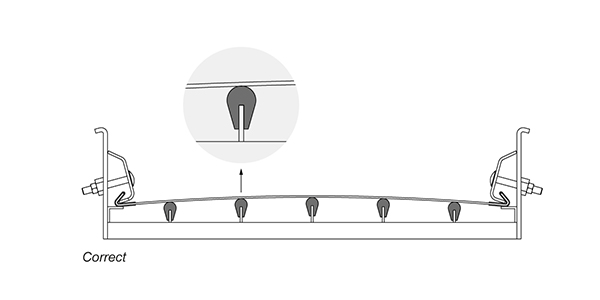

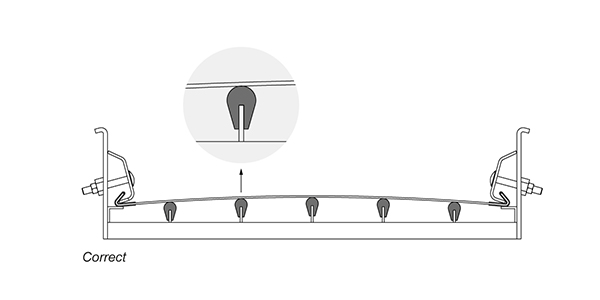

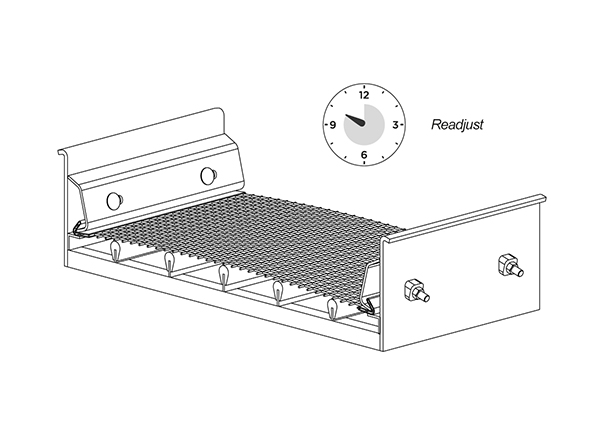

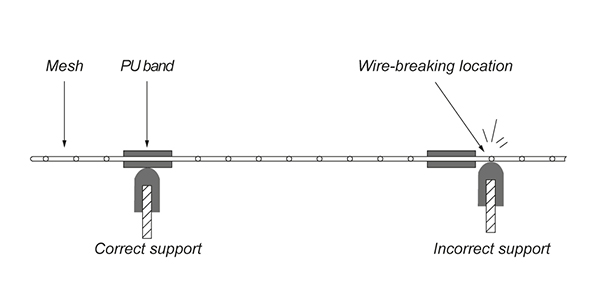

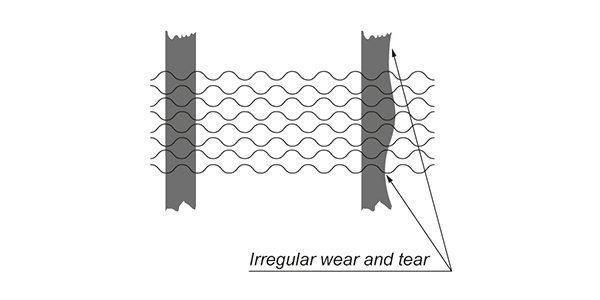

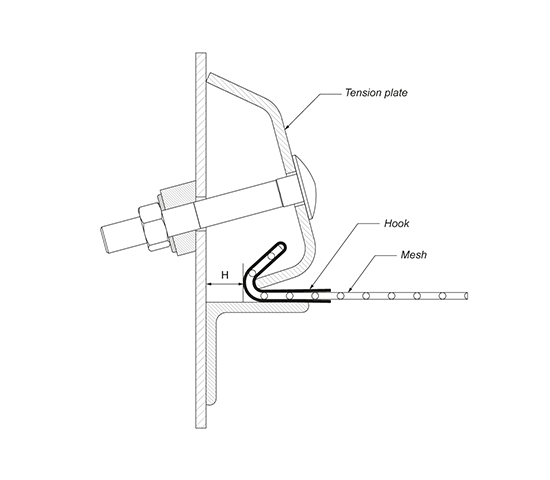

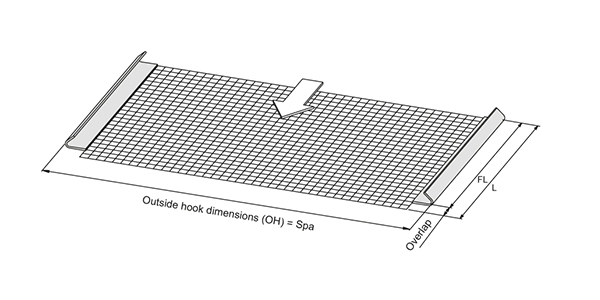

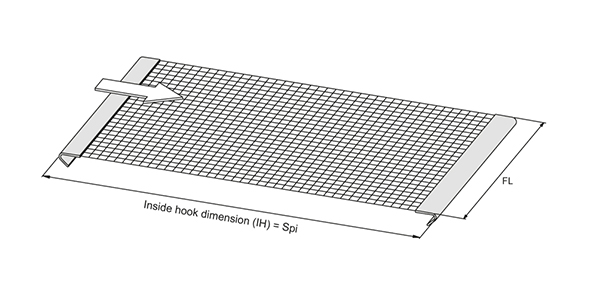

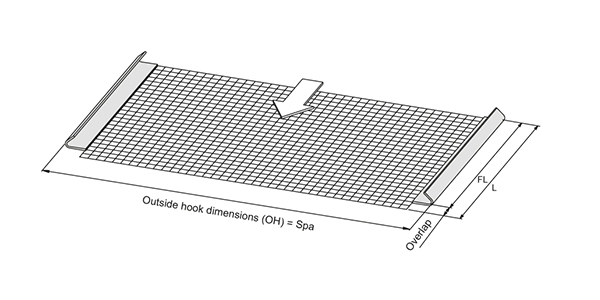

· Check that the and re-check this at regular intervals. This is the main cause of premature screen failure. If the screen is loose it will be vibrating and banging the support bars, creating micro fractures along the support bar that will result in screen damage. Also make sure to allow enough space (H) on both sides of the screen to tighten it symmetrically, the hook of the screen should never touch the machine’s side.

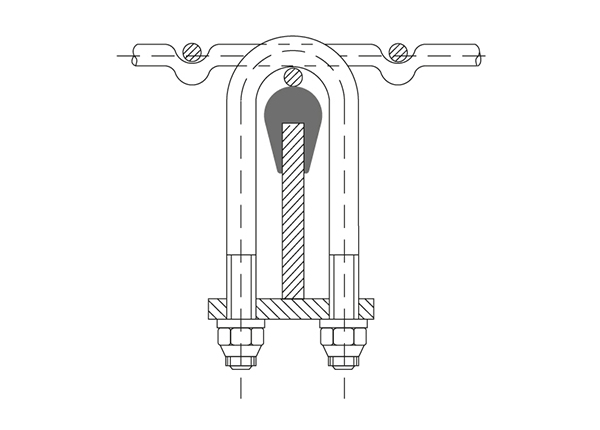

If you are using metallic screens with wire diameter over 6.3mm. you may need to use U-Bars or J-Bars to fix the mesh to the screen deck.

On meshes with thick wires, greater than 6.3 mm, there is the possibility of the tension plates coming loose despite having tightened the screws. It is necessary to check and retighten after ten hours of screening.

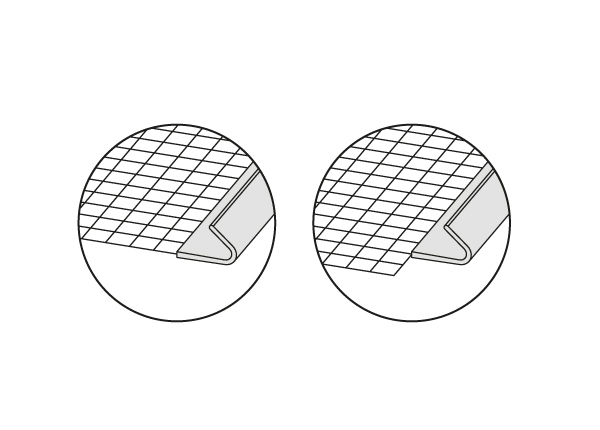

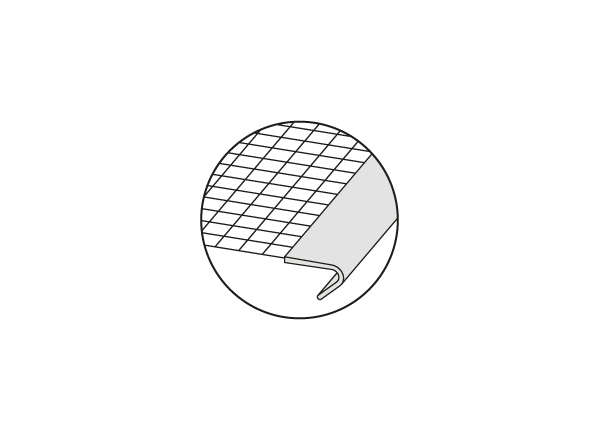

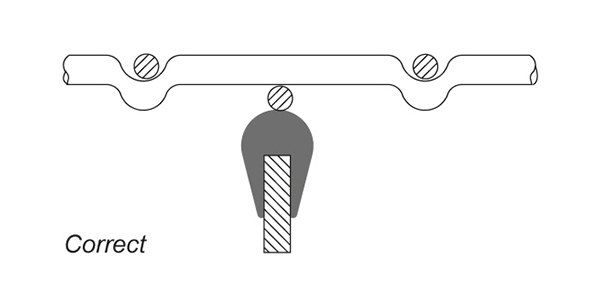

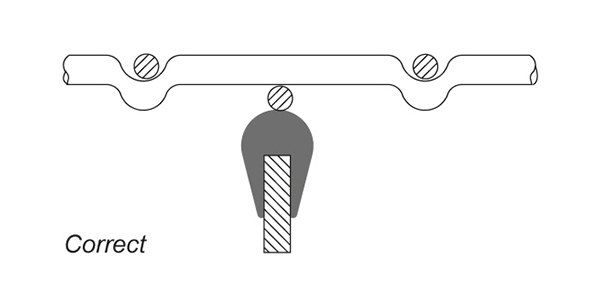

· Check that the side plate fits correctly on the screen’s hook (1). If the side plate touches point , the hook will turn, breaking the mesh at point 3

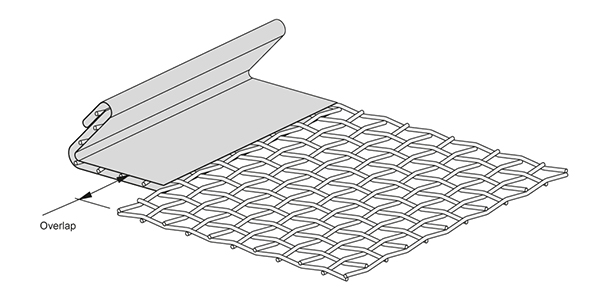

Metallic overlap

Polyurethane overlap

Side tension

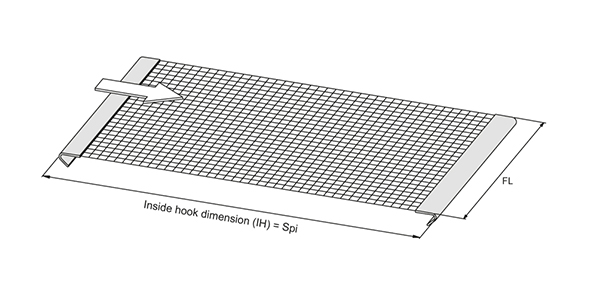

End tension

Split side tension – Type 1

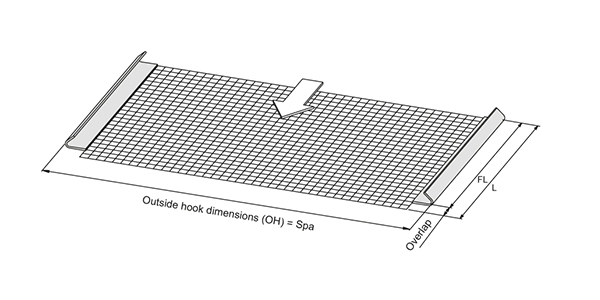

S type end tension

Split side tension – Type 2

without overlap / with overlap

without overlap screening